An Interesting Approach to the Product Installation Process

AYAX RANGEL | Spring 2018

Reprinted with permission from Simple Solutions That Work!

ARTICLE TAKEAWAYS:

- When materials, methods, machines, and EH&S are considered in the planning stage, the chances of a successful installation are higher.

- Planning ahead, open communication channels, and getting to know the key factors is important.

- Agreeing with customers on the required specifications and lab data will help to build on the confidence level.

- Knowing how to balance the assets and capabilities.

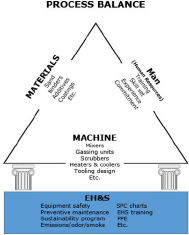

I always have believed that to successfully implement a new resin system in an existing or new customer, it is necessary to take into consideration four important factors: Materials, Methods, Manpower, and EH&S. The first three represent a three-sided equilateral triangle, which in turn is being supported by safe practices and products. If any of the sides of the triangle are unbalanced, the chances of carrying out a successful implementation could be compromised. Any substantial deficiency of any of the 3 M's (Materials, Methods, Manpower), will require that the other two be challenged at a higher degree.

For example, if a premium binder system is introduced to a core room, but the coremaking equipment is deficient, then, the binder system may not perform to its fullest, and the staffing may also have to be tested to make the system work on a consistent basis. On the other hand, if the foundry makes the effort to invest in state of the art equipment and binders, but the staffing is not properly trained or proficient on the new technology or materials, the foundry may not fully garnish the full competitive advantage the new investment in equipment and products. Be aware that this does not mean if new equipment, expensive materials, or costly training are not used, the implementation will not be successful.

By applying this philosophy will you guarantee a successful implementation? Of course not. As in any other thing in life, the key of success resides on effectively balancing all the assets and capabilities on hand to maximize the outcome. In many ways a successful implementation is the result of achieving a sustainable degree of consistency in the coremaking or molding process as well as meeting process specifications established as a goal of the conversion. Below is a brief summary of an actual application of this philosophy.

Months ago we received a request by a leading casting supplier for mining and construction equipment. The main objective for this company was to test and access new products that could help them to maintain their competitive edge. Of course, two of the main initial requirements were competitive pricing and compliance to specifications in their current process (curing speed, mechanical strengths, mold and casting scrap level, etc.). The initial conference calls with the management team opened the chance to present HAI's product portfolio, team, and capabilities, but more importantly it opened the communication channels that would be key to fully understanding their requirements at the plant /core making level. With the information gathered, a product proposal was submitted. Additionally, HAI requested the opportunity to visit the foundry to make sure the products originally proposed fully complied with the requirements and expectations.

As a leader in the foundry consumable products; investing the necessary resources in assessing customer's facilities has proven to be consequential in understanding a particular customer's methods and equipment. Instead of matching a current product's performance, a joint approach was initiated. This approach enabled us to understand the equipment capabilities and staffing experience / skill level, which in turn allowed us to make a functional decision on the product mix that we believed would best fit this operation. During the facility review, we also observed and became familiar with the foundry's process equipment, packaging, and logistics challenges; all of which are important in the product recommendation and implementation process.

It is also important to understand that the opportunities for success are diminished if there is not an active collaboration on the part of the client. Once the client's requirements and expectations were understood, we assured that our laboratory testing protocols best matched the client's QA lab. Hence, during the visit we documented testing protocols to be replicated in the HAI laboratory. We also gathered molding materials such as sand and additives so that the lab results could be relevant to the foundry. Production samples were also collected for comparison of HAI and customer lab equipment. This crosschecking test was key in building up confidence for both parties and ensuring that the product selection was on the right track.

During the subsequent visits we were able to become better acquainted with the operators and their different skill levels. The people at the foundry, were very positive and receptive to the idea of testing new products and the potential benefits associated. The interaction with the foundry staff was positive as we had the chance to enhance their understanding on the best practices and attributes of the products to be tested. This information exchange was important in order to be able to adjust the product mix as a function of the customer's capabilities and methods; coremaking, handling, storing, as well as environmental conditions.

All of the aforementioned information, along with the client visits and opportunity to meet and work with the foundry staff, allowed us to present an improved proposal for a product that has a higher chance of a successful implementation of a proposal backed by lab data relevant to the foundry. This new improved product mix should not only meet the customer's technical requirements, but also both parties were able to anticipate potential challenges during the implementation process. One important feature sought by the customer that was not initially identified in the initial request was the desire to have a product that displays low odor at coremaking and smoke at the pouring, cooling, and shake out process. This characteristic, which originally was considered a standard feature, turned out to be a key differentiating factor after further discussion at the foundry. Again, a low odor / smoke attribute as a competitive advantage may not have been completely understood had we not had a close collaboration with the customer.

In the end, what are the advantages of taking into consideration Materials, Methods, Manpower, and EH&S in the implementation process? Are the additional resources and time invested by customers and suppliers alike worth pursuing? Each case is different, as are each foundry and supplier, each of which may favor their unique methodology for the implementation process. Eventually, you will have to decide whether or not this approach is worth considering. This may be a worthwhile approach in your implementation tool box.

.png?width=268&height=81&name=logo-new2%20(1).png)