Optimizing Your Foundry Operation Via Optimized Risering Practice

AARON KABOFF | Spring 2022

Reprinted with permission from Simple Solutions That Work!

Download PDF: English

- Who is your solutions partner during difficult times?

- Importance of US alternative solutions

By the end of 2020 many hoped that 2021 would be a rebounding year for the metal casting industry. On the contrary the stark reality is that 2021 has proven to be one of the toughest years that the metal casting industry has ever experienced.

The reality of rapid cost escalation for raw materials was quickly worsened by news of shortages and tight supply of key raw materials to make finished goods. If the cost escalations were not enough, when raw materials could be found and purchased (even at very high prices), ensuring a reliable supply chain was nearly impossible. Products that routinely carried a lead time of four weeks were suddenly being delayed 10 to 12 weeks, with no prior notice. The situation is particularly tight for materials being sea-freighted, which has triggered significant back logs in trucking and rail. There are many motives associated with this surge in prices and tight supply, from the disruptions in sea-freight in the Suez Channel, big backlogs in entry ports, deep freezes in the gulf region, to traversing many geopolitical situations. The situation has turned even more critical as the pent up demand for products and services has risen steadily throughout the year.

This challenge was not just purview to tight supplies in petrochemicals and its byproducts, but the difficult situation permeated to essentially most, if not all, the chemicals/ products necessary for the various stages of the casting process. From phenolic, shell, furan, and inorganic resins, to pretty much all types of catalysts and coreactants for foundry binders, refractory coatings, shell sand, and even auxiliary products such as releases and glues are affected. The situation was so precarious that even the packaging used to package the products such as drums, totes, cardboard boxes, and wood pallets became a highly expensive and sought after commodity as its own package services also saw price increases and Issues with availability as well.

Unfortunately, the situation continues to be precarious at best. Although the situation with some key chemicals have softened and become more available, there are new chemicals and products constantly being adding to the list. At this moment, and depending on the particular product or products that a foundry or a core shop uses in the casting process, the situation continues to range from tight to severe.

WHEN THE WORD “SOLUTIONS†REALLY MATTERS!

As all of the aforementioned challenges faced by foundry suppliers impacted the ability of foundries and core shops to produce castings on time, on budget, and with the consistency and quality required, our mindset to being a fast forward solutions oriented enterprise shifted into overdrive. This wasn’t a new mindset, but rather now had to implement all that we have prepared for in order to rapidly respond to these new and seemingly insurmountable challenges. The necessity to deliver our clients the necessary products in order to avoid unnecessary havoc has boosted our creativity to respond to today’s challenges. This rapid response provides cohesion among our functional groups. This cohesiveness provides an agile way that quickly speeds up an integration of service and products to be configured to address each customer’s specific need.

The following are five actions that exemplify the Solutions Provider mindset aimed at helping and supporting foundries and coreshops.

1. FIRST PRIORITIES FIRST

When this current raw materials crisis started early in the year, our main responsibility was, and still is, focused on keeping our customers whole. As key raw materials became tight, prices rose, as well as did freight cost. In spite of these hurdles, we understood that securing raw materials and finished goods to our customer base is critical. Hence, we worked extensively on several supply agreements with key suppliers and global partners to keep the necessary allocation flowing in. We are fortunate to be part of HA Group. A global enterprise whose affiliates work together in times of crisis to be creative in finding sustainable solutions. We also had to make a decision on ordering products way ahead of time, although the demand forecast in order to secure the key raw materials to manufacture and ship the products was not yet set in stone.

2. REPLACEMENT PRODUCTS

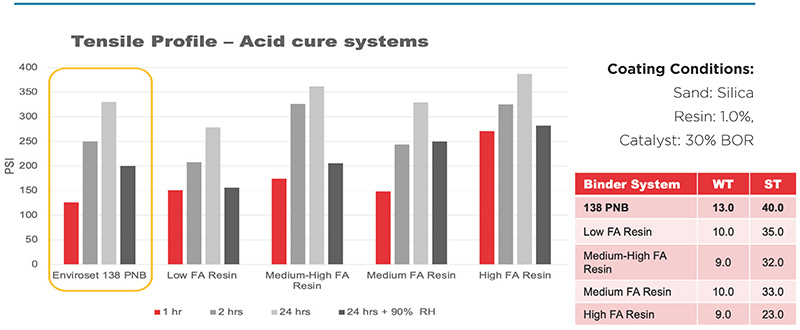

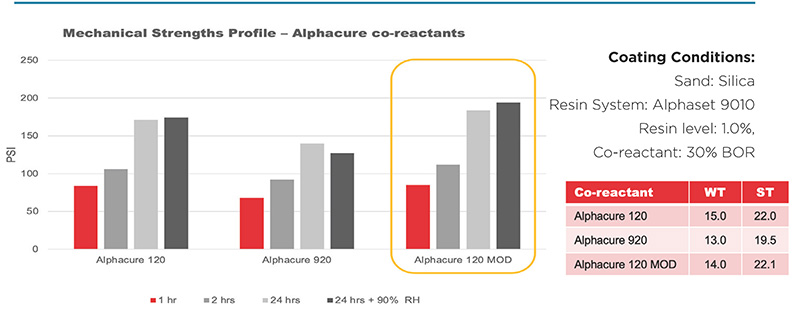

In spite of the extraordinary efforts made in securing the necessary materials, many times we faced allocations or even force majeure. In those instances in which the product prices were significantly increased, or when the supply for those products remains extremely tight, we have put forward a set of replacement products that could offer temporary relief (economical or supply assurance). It is important to mention that the application of these alternative products may result in some trade off adopting a new process or technology, which is the reason why point five “Partnering with our customers†is a key success factor to be considered. The following graphs show some examples of case replacement products that can offer an immediate relief.

One emerging replacement product than can offset the rise in pricing of Furfuryl Alcohol Resins is the Phenolic Modified Resin No-Bake (PNB) system. During a time where Furfuryl Alcohol is in limited supply, as well as being at all time high prices, PNB systems are able to offer similar strengths as other furan resins with the ability to have a “drop-in†replacement that would require very little change by making the switch. On top of having similar characteristics, it also boasts the benefits of having more readily available raw materials as well as a lower cost alternative during these times of inflated prices.

3. INVESTING IN DOMESTIC SOLUTIONS

While many suppliers are divesting on their operations by decreasing their manufacturing footprint in the US, removing technical services and applications lab services, we believe that bringing back the manufacturing capabilities of products makes sense. It is true that not all products can be made in-house nor all raw materials can be procured from sources inside the US. However, suppliers that invest in domestic solutions to manufacture their products not only sends a strong signal of commitment, but also greatly mitigates the impact of unreliable and costly logistics, sudden supply chain disruptions, and other problems that can manifest in shortages and higher prices.

Agile and flexible manufacturing - Toledo transformation from a coatings only plant to a multipurpose manufacturing plant has helped HAI customers to obtain more products made by HAI in the US.

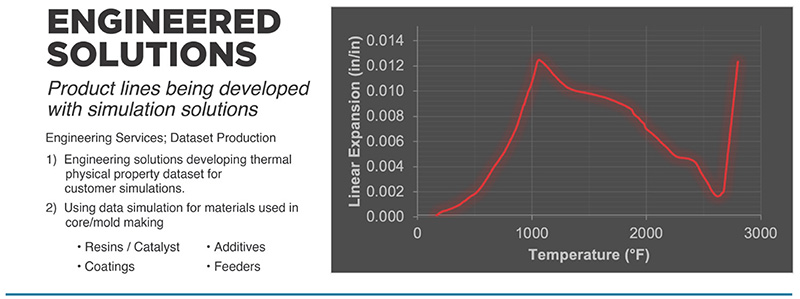

4. CREATIVE ENGINEERING AND R&D

Sometimes a commercially available replacement product may not be a feasible solution. In this case, a true solutions oriented supplier puts their creative effort toward creating, reformulating, and implementing new products and that can address the crisis at-hand. This current crisis has sparked a new sense of urgency in which our chemists and engineers have benchmarked, screened, and qualified many new raw materials that are more cost effective and feasible, which have be used to create new products that exhibit the same or sometimes improved characteristics as the original products. Reengineering current technology by adjusting or modifying their raw materials make up is another approach to providing sensible solutions to foundries. All of this work requires an intimate knowledge of the interdependency between the base chemistry and the practical application know how and all the while maintaining a close collaborative relationship with the customer at the implementation/ adopting phase, which is why the fifth action in partnering with customers is one of the most important manifestations of a solutions oriented supplier.

On the other hand, occasionally the solution to a product shortage is the adoption of a new process, which includes varying products, when combined together provides the appropriate solution. In this instance, relying on a reliable applications engineering function is of vital importance in the implementation of customized solutions.

5. PARTNERING WITH OUR CUSTOMERS

Implementation of a solution requires much more than merely bringing a new or replacement product to the customer. Without the proper support at this phase, most of the time, the new product delivers more stress to the customer, thus the implementation of the solution by collaborating with the customer is just as important to the overall success. The ability to test in a suitable applications lab by first using the customer’s specific requirements and conditions, and then supporting the implementation in production, improves the chance that the solution sought after is met. Many times this added value is not taken into account, but this is yet another example of the commitment of the supplier to ensure that client conditions and requests are met.

CONCLUSION

Many of the challenges that the foundry industry has faced in 2021 will persist into 2022. This past year has demonstrated the resilience of many foundries in extreme adverse conditions. The solutions to today’s shortages in products and disruption in supply chains may stay with us for the foreseeable future. Finding and partnering with suppliers that truly live the mission “Solutions Oriented†is one of the most solid decisions to ensure that your business is not only in a solid position to not overcome current and future difficulties, but also to turn them to opportunities.

.png?width=268&height=81&name=logo-new2%20(1).png)