Zircon-Free Coatings

High Performance - No Compromise

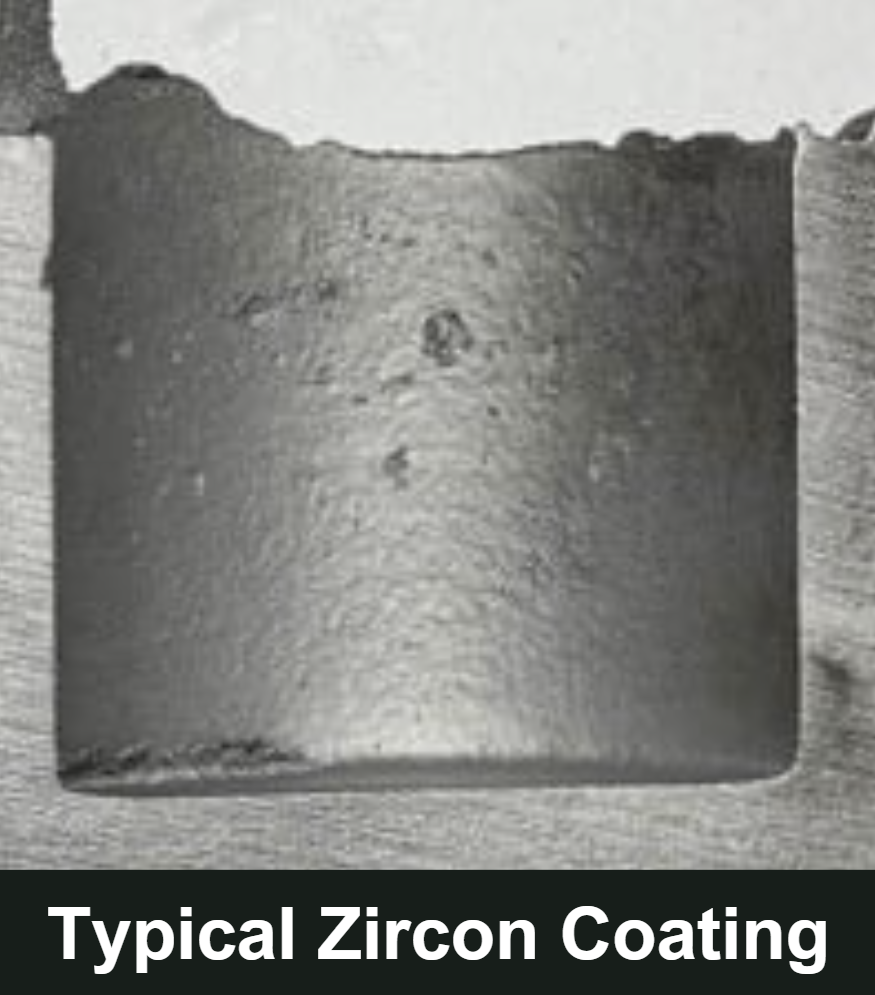

No-bake foundries, also known as the jobbing market, depend heavily on the application of refractory coatings to ensure high-quality casting production. Due to the size and heat demands of the castings, zircon coatings are commonly used. These coatings are essential for large, heavy section thicknesses in iron and steel castings, as they offer high refractory value to meet the necessary performance standards.

Problem Statement

Zircon flour has experienced issues with availability due to market instability, leading to increased prices. This supply chain uncertainty, combined with the rising costs of zircon, has posed significant challenges for foundries over the years. Additionally, the radioactivity of zircon creates further complications for disposal and handling, increasing operational costs and regulatory hurdles.

Solution

In response to these challenges, HA has developed alternative zircon coatings that offer comparable performance while reducing costs. These alternative coatings deliver similar results to zircon coatings, making them a more cost-effective and practical solution for foundries facing supply and pricing issues, as well as regulatory concerns.

Key Benefits of Zircon-Free Coatings

- Stable Supply Chain & Pricing

- Radioactive Free

- Simplified Disposal

Product Offering

- Our products are available in both water-based and alcohol options.

- The water-based product offers a color change option.

- The product mixes easily for smooth application.

- It delivers a flawless finish with excellent results.

- Suitable for all application methods: brush, swab, flow coat, and dip.

- Brush application ensures a smooth, mark-free finish.

Casting Performance

Learn about Refractory Coatings

A good refractory coating can bring significant value to your operation through improved surface finish or reduced cleaning costs. Refractory coatings are a complex mixture of ingredients in which each plays a part in the final product's application characteristics, stability, surface finish, resistance to cast defects, and cost. Be sure to contact your HAI sales representative to determine which coating best fits your foundry's needs.

To learn more about refractory coatings, download our complete Refractory Coating Brochure.

Your contact

Daniel Cygal

Product Manager Coatings

.png?width=350&height=350&name=Untitled%20design%20(35).png)

.png?width=268&height=81&name=logo-new2%20(1).png)